Plastic regranulates

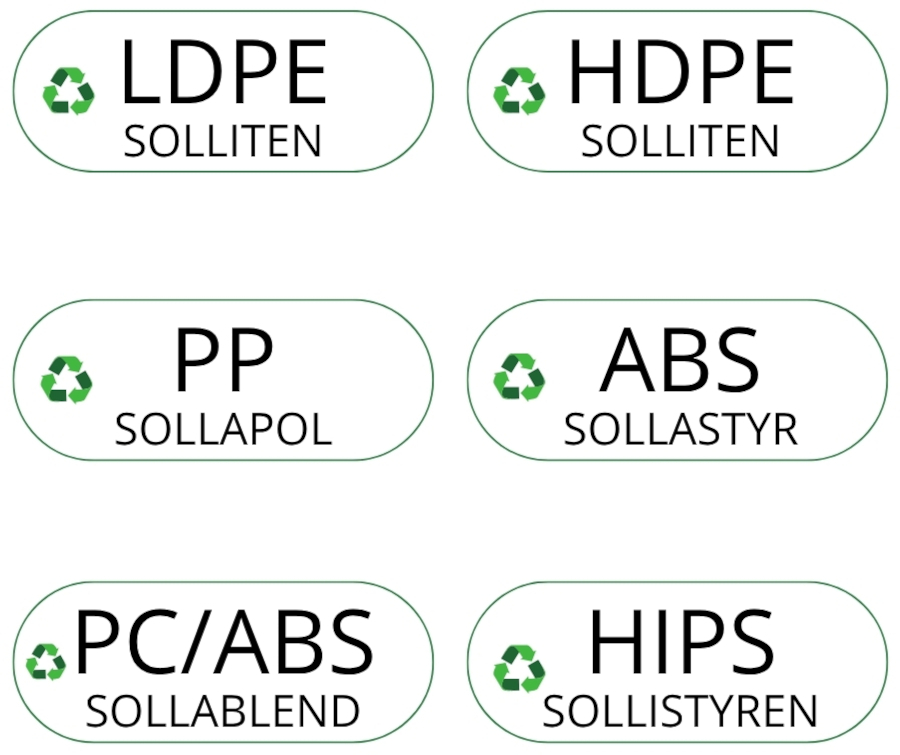

Choosing the right re-granulate is not always easy. Each operation has different requirements, machines, or standards. That is why we offer up to 6 different types of plastic re-granulates.

If none of the available types meets your exact needs, we can also provide a custom-made re-granulate - according to your required parameters, color, melt flow, or packaging.

Want to check if our re-granulate meets your production requirements?

We will be happy to send you a free sample.

We offer a wide range of plastic regranulates

Choosing the right re-granulate is not always easy. Each operation has different requirements, machines, or standards. That is why we offer up to 6 different types of plastic re-granulates.

If none of the available types meets your exact needs, we can also provide a custom-made re-granulate - according to your required parameters, color, melt flow, or packaging.

Want to check if our re-granulate meets your production requirements?

We will be happy to send you a free sample.

Order a free sample of plastic regrinds

Technical data sheets of SOLLAU CZ s.r.o. regranulates

| Material | Color | Type |

|---|---|---|

| HDPE SOLLITEN | black | extrusion |

| LDPE SOLLITEN | translucent | extrusion / blowing |

| PP SOLLAPOL | black | injection |

| PP SOLLAPOL | natur | injection |

| PP SOLLAPOL | grey | injection |

| HIPS SOLLISTYREN | white | injection |

Why the regranulates from SOLLAU CZ?

NaWe always respond to your demands by return

We have most products in stock immediately

Products meet the highest quality requirements

We have our laboratory for testing

INTERESTING FACT

Re-granulate is more cost-effective than primary material.

Re-granulate is more cost-effective than primary material.

Incorporating re-granulate into production can reduce costs by up to 20 % compared to using primary granulate, without significantly impacting the final product quality.

Need fast and reliable material delivery?

A supply failure or delay means complications and losses for production. By keeping key types of re-granulates in stock, we can react quickly and without unnecessary waiting.

Are you looking for ways to reduce input material costs without compromising?

Primary granulates represent a significant item in the production costs. But if you do not want to compromise on quality, re-granulate is an effective solution. Our plastic re-granulates offer significantly lower costs while maintaining stable parameters and processability.

Need to be sure that the material matches your requirements?

Our experience shows that many suppliers offer only limited or incomplete information regarding the re-granulate. With us, it is different - thanks to our laboratory, we have detailed control over every material.

FAQ

Plastic re-granulate is a recycled material that comes from processing plastic waste. This process involves sorting, grinding, cleaning, and subsequently melting the plastic to create a new granulate suitable for further production.

Re-granulates are widely used in various industrial branches. They are used, e. g., in the production of packaging materials, technical parts, pipes, furniture, or building components.

Yes. Primary granulate is made from new raw materials, while re-granulate comes from recycled plastic waste.

The re-granulate production involves several steps: sorting of plastic waste, its shredding, cleaning of impurities, drying, and subsequent melting. The material produced through this process is formed into granules ready for further processing.

It reduces production costs, saves natural resources, and supports sustainability. In addition, it contributes to reducing plastic waste and greenhouse gas emissions.

Need quality and sustainable materials for your production? Plastic re-granulate can be an ideal choice. Contact us - we will help you find a solution that makes sense.