MSP-MC Pipeline magnetic separator

The MSP-MC separator is configured to remove weak magnetic contamination from powder and liquid processing lines.

Design of the magnetic separator MPS-MC

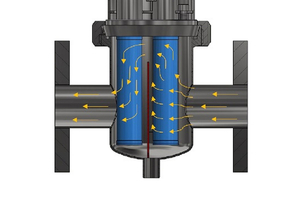

The MSP-MC separator consists of a set of magnetic tubes (whose cores are covered by protective stainless steel tubes). The first row of tubes always contains one magnetic tube less than the next row. Thus, the magnetic tubes of the first row cover the gap between the tubes of the next row. Thanks to this arrangement, the cleaned material flows through a dense sieve and the extremely strong field of neodymium magnets captures all magnetic particles on the surface of the protective tubes.

Operation mode

This magnetic separator is equipped with very strong neodymium cores and that is why it catches also very small ferromagnetic particles. The already caught particles migrate to the backside of the protective stainless steel tubes (and that is why these particles are not washed off by the continuously flowing material).

Cleaning mode

In case of smaller versions of this separator, these are cleaned in the similar way like most of the grid separators with an easy cleaning system. The separator body is removed from the pipeline, the magnetic cores are moved to the upper position by means of a lever and the iron contaminants (held on the protective tubes' surface by the magnetic field) fall off spontaneously. The easy cleaning system (unlike the fixed magnetic grates whose cores cannot be taken out during the cleaning) has a number of advantages: the cleaning is fast and easy, the caught contaminants don't need to be laboriously removed from the grid surface, the life of the protective tubes is extended and the risk of injury with a metal particle in the course of cleaning has been also eliminated.

However, if there is to be applied a bigger variant of the separator of if the material is heavily contaminated, it is recommended to use a magnetic separator with semi-automatic (MSP-SC) or fully automatic cleaning (MSP-AC).

Other advantages of the separator MSP-MC

a peephole (for the optical inspection of the magnetic tubes as well as of the material flow)

a peephole (for the optical inspection of the magnetic tubes as well as of the material flow)- an integrated lock of the magnetic tubes (preventing unauthorized persons from tampering with the separator)

- a chambered system ensuring the exposition of the liquid to extremely strong magnetic field for maximum time (there is achieved the best possible efficiency of the magnetic separation, as the entire length of the magnetic tubes is utilized)

- a mesh (capturing even larger non-ferrous contaminants)

Max. magnetic induction: up to 18 700 Gauss on the magnetic core and up to 12 200 Gauss on the surface of the protective tubes (with a tolerance of +/- 10%).