VMSV High intensity rare earth roll separator

The VMSV multi-stage dry high intensity rare earth separator with very strong magnetic rollers is used for the automatic and continuous separation of fine, weakly magnetic and paramagnetic particles (including stainless steel).

Design of the high-intensity magnetic separator VMSV

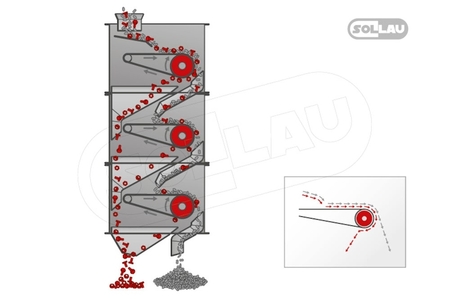

Depending on the model line, this separator is equipped with either a vibrating feeder (VMSV variant) or a feed roller (VMSV-EKO type) and several pairs of rolls placed above each other. One roll of the pair is always a driving one (with a magnetic core) and the other, non-magnetic, is a driven one. The pairs of rolls drive a very thin, nevertheless, a very resistant conveyor belt (made of e.g. kevlar, fiberglass, a non-sticky material etc.).

Operation mode

The material loosened by the vibratory feeder or the feed roller falls down onto the conveyor belt of the magnetic separator. As the material moves into the separation zone of the magnetic head pulley, magnetically-susceptible particles are attracted towards the high intensity magnetic poles. The trajectory of the particles affected by the high-strength magnetic field is altered and these particles are carried outside the magnetic field of the roll and fall off to the discharge outlet.

The purified (non-magnetic material) continues to flow in a normal trajectory and falls spontaneously (by gravitation) on the next conveyor belt (positioned under the first one) and the separation process is repeated in the already above described way.

The separator can be fitted with such a number of magnetic rolls that will guarantee the material purity according the client's needs.

With a carefully positioned splitter, the two fractions – magnetically susceptible materials and non-magnetics – are separated from each other. The splitter position is angularly and axially adjustable (again according to the client’s needs and the properties of the cleaned material), and that is why in some applications it is possible to create a third (so called ‘middlings’) fraction consisting of weakly magnetic particles.

The device is equipped with extremely strong magnets with a very short magnetic reach (of max. 10 mm). Therefore, the basic conditions for the separation of very small, weakly magnetic or paramagnetic particles include the formation of a uniform and the lowest material layer possible on the separator belt (if feasible, the layer height should not exceed the maximum material size and it should be a monolayer). That is why it is recommended that the height of the material transported on the belt does not exceed 5 mm and if the client wants to achieve the maximum possible efficiency, we recommend that the material height of the layer is up to 2 mm.

If there are applied extremely thin conveyor belts (e. g., from kevlar or glass-teflon), the maximum size of material fraction should not exceed 5 mm (larger particles could damage these special conveyor belts). There could be used (in case of coarser of more abrasive materials) reinforced conveyor belts, however, the application of thicker belts reduces the separation efficiency (as due to the belt thickness the ferromagnetic particles may get out of reach of the magnetic field of the roll).

The filling hopper, whose dimensions correspond with the width of the conveyor belt, is an integral part of the vibratory feeder. The optimal material dosing on the separator belt is performed either by the vibration controller (VMSV) or by the rotation speed change of the feed roller (VMSV-EKO). The separator also includes a set of sensors ensuring the safety and smoothness of the separation procedure. E. g., if any inspection opening is opened during operation, the entire device will immediately switch off automatically. There is also a sensor monitoring the height of the material layer, and this sensor prevents blocking of the separator by the separated ferromagnetic particles if the discharge outlet is clogged.

The permanent multi-stage separator is delivered with a special device for an easy and quick adjustment of the optimal conveyor belt tension. Besides, in case of the VMSV version, each drive roll motor is equipped with a variable speed unit (in order to set a different speed for each of the belts, which significantly increases the separation effectiveness).