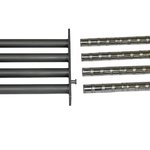

MR Magnetic grids

The grid magnets separate ferrous contaminants from freely flowing material of good bulk properties. Thanks to the use of extremely strong neodymium magnets, the grid is able to separate even paramagnetic or weakly magnetic particles (e.g. stainless steel). By means of the easy cleaning system (i. e., by sliding the magnet cores out of the protective tubes) the trapped metal particles can be quickly and comfortably removed from the grid.

Cleaning mode

Like most of grid separators with an easy cleaning system, also the magnetic grates are cleaned by sliding the magnet cores out of the protective tubes. Iron contaminants held on the tubes' surface by the magnetic field will fall off spontaneously.

Main advantages of magnetic grids

The easy cleaning system (unlike the fixed magnetic grates whose cores cannot be taken out during the cleaning) has a number of advantages: the cleaning is fast and easy, the caught contaminants don't need to be laboriously removed from the grid surface, the life of the protective tubes is extended and the risk of injury with a metal particle in the course of cleaning has been also eliminated. Besides, there are other benefits: high efficiency, low acquisition and maintenance costs; high versatility - magnetic grids are used in hoppers, silos as well as for cleaning free-falling or conveyed materials etc.

Operation mode

The grate magnet is equipped with very strong neodymium cores and that is why it catches also very small ferromagnetic particles. The already caught particles migrate to the lower part of the protective stainless steel tubes (and that is why these particles are not washed off by the continuously flowing material).

Max. magnetic induction: up to 12 000 Gauss on the magnetic core and up to 9 800 Gauss on the surface of the protective tubes (with a tolerance of +/- 10%).