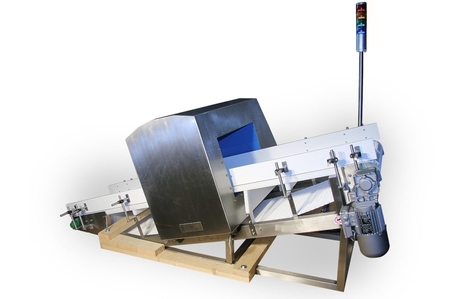

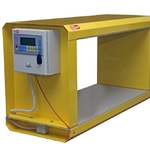

TDK Belt conveyor metal detector

The metal detectors for belt conveyors are designed to detect and then reject any kind of metal from a belt conveyor system.

Mode of operation

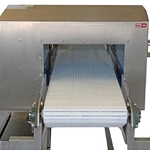

The basic element of each detector is a detection head fitted with electromagnetic coils. When an unwanted metal contaminant exceeding a pre-set sensitivity is detected in the material or packed product transported on the conveyor belt, the search coil of the tunnel detector sends a signal to the control unit. Depending on the programmed sensitivity and the detector equipment, the detector afterwards perform ones of the following operations:

- the conveyor belt is stopped (the suspicious object or material can be marked by a marking device or its presence signalized by an sound or light signal). The object will be subsequently removed from the conveyor belt manually by the operator.

- the detected object is automatically removed from the belt. For its removal can be used a diverter arm, an air blast, a pusher arm, a power decliner, a carriage retract etc.

Sensitivity setting

Thanks to the touch screen, the detector's reaction to a number of potential situations can be pre-set easily. Depending on the model, a wide range of functional parameters can be programmed; the information about the current situation can be displayed on the integrated monitor as well.

Individual equipment

The basic parameters (i.e. the length, width and height of the aperture head, dimensions of the conveyor belt etc.) result from the particular application. The conveyors' detection system can be equipped with, e. g., a device for stopping the belt (the so-called belt stop alarm), which signalizes a detected contaminant and stops the conveyor belt simultaneously. The tunnel detector can also be supplied in a height-adjustable version, with wheels (for easy handling and transport), with light or sound signalization and with a belt speed regulator. There are also a number of elements for rejecting the detected contaminant: an air nozzle, a pusher, a carriage retract, a diverter, a plough, a power decliner etc. Other optional equipment includes tamper-protection by a password, internal diagnostics of the current device status, interface connection (for PC or wi-fi) etc. High sensitivity, top quality workmanship, robust design and up-to-date SW and HW equipment guarantee a long and trouble-free operation.