Mobile crushing and separation line

The mobile crushing line is designed for the immediate processing of post-industrial plastic waste. We have equipped the line with a complete set of appliances, so we can crush the processed plastics, remove the dust and get rid of unwanted metal particles (magnetic as well as non-magnetic). The crushed material is stored directly in a big bag, which is also suitable for its subsequent handling.

The mobile crushing line is designed for the immediate processing of post-industrial plastic waste. We have equipped the line with a complete set of appliances, so we can crush the processed plastics, remove the dust and get rid of unwanted metal particles (magnetic as well as non-magnetic). The crushed material is stored directly in a big bag, which is also suitable for its subsequent handling.

As the manufacturer of this crushing and separation line, we can adapt the individual components to your requirements.

As the manufacturer of this crushing and separation line, we can adapt the individual components to your requirements.

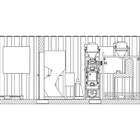

The fundamental benefit of this mobile crushing and separation line is that all the equipment for plastic processing is placed in a unique sea container. Therefore complete crushing, dedusting and metal separation can be performed on-site. So, the line can be equipped with a crusher, a deduster, a magnetic separator, a metal detector and other appliances needed to fill plastic regrind into big bags. This container can be directly placed in the plastics processing plant (indoor as well as outdoor, according to the customer's needs). The container is fitted with a complete crushing and separation technology and that is why the post production waste (overflows, cutoffs, non-conforming parts, etc.) can be processed directly at the customer's site. In such a way the client is provided with high-quality plastic regrind which can be consequently reused for plastics production.

The main advantage consists in the fact that there is no need of demanding and expensive logistics = it is not necessary to transport the post production plastics for crushing outside the company and afterwards get the regrind back. Thanks to this, the price of the plastic regrind can be significantly reduced. Simply said, you will put the plastics to be crushed into the container on one side and you will pick up a big bag with the plastic regrind on the other side.

So let the crushing technology travel to the material, not the material to the technology = significant cost reduction!

Advantages of the crushing line

- 1On-site processing of plastics

- 2Elimination of transport costs

- 3Flexibility - you will process plastics at the time when it is suitable for you. You can quickly react to production requirements for the material.

- 4Direct monitoring of the regrind quality

- 5Compact design – installation in the sea container. Complete technology at one place (crusher, dedusting device, magnetic separator, metal detector, big bag filling station)

- 6Complete wiring system and interconnection of technologies – just plug it in, no additional care is needed.

- 7Mobile device – the container can be transported e. g., between your individual plants.

Security and user comfort

For reasons of work safety, the entire technology (crusher, dedusting device, magnetic separator, metal detector) is separated by a folding door. Thus, only the opening for inserting materials into the crusher is accessible.

This line is fully equipped and provides sufficient comfort and safety for the operators. It is fitted out with an electric thermal unit, allowing regulation of the temperature in the container.

This line is fully equipped and provides sufficient comfort and safety for the operators. It is fitted out with an electric thermal unit, allowing regulation of the temperature in the container.

The mobile line includes a complete electrical installation and an independent electric meter for accurate monitoring of electricity consumption. First-rate lighting of the workplace interior is taken for granted.

Technology

ZERMA GSE 300/600 granulator

- High-speed granulator - suitable for grinding e. g. rejected smaller plastic parts

- Capacity 150 - 750 kg / hour depending on a material type

- Rotor diameter: 300 mm

- Rotor width: 600 mm

- Driving power: 11 kW

OZ 1200 Dust collector

- Capacity: 1200 kg/hour

- The minimum particle size which can be captured by the OZ: 520 - 620 microns

MSS-MC 150/5 N Magnetic separator

- Capacity: 7 m3 / hour

- Two-stage separation

- Magnetic induction: 18 700 G

QUICKTRON 03 R 100 Metal detector

- Capacity: 11200 l / hour

- Detector sensitivity: Fe ball ø 1.0 mm

External dimensions of the mobile line

- Length: 606 cm

- Width: 244 cm

- Height: 259 cm