WHC High-Speed Mills

WHC high-speed mills (plastic crushers) are high-performance machines designed for efficient processing of plastic materials (PE, PP, PVC, PET, ABS...).They are suitable for recycling large plastic parts such as appliance covers or car bumpers.

SOLLAU CZ: Exclusive representation of WOBIDE mills and crushers for the Czech Republic, Slovakia and PL!

Their advanced design ensures long life and high performance. The RM Series Crushers can handle a wide range of plastics and rubbers. Their rotors can be tailored to specific applications.

High-Speed Mills mean reliable performance, fast service, and available spare parts!

The WHC series of high-speed mills offer an excellent price/performance ratio. However, this does not mean a compromise in quality. It has 30 years of experience in the plastics recycling industry and a professional approach at all levels of the production process that speak for themselves.

- All shredders are manufactured under strict European standards, as evidenced by CE certification and production acc. to ISO 9001 standards.

- Key components such as control electronics are sourced exclusively from renowned European manufacturers Schneider and ABB, guaranteeing long-term reliability and trouble-free operation of the shredders.

Customized main shaft

Customized main shaft

- The main shaft is made of highly durable welded steel with a unique V-shaped design.

- All main shafts have been subjected to rigorous dynamic and static balance tests, ensuring reliable and trouble-free operation.

Outer bearing seating

Outer bearing seating

The main shaft and the machine body are sealed with a sealing ring, which effectively prevents the ingress of crushed materials into the bearing and thus extends its lifetime.

Hydraulic opening system

Hydraulic opening system

The upper and lower cover and the sieve holder are hydraulically operated. It is convenient for machine maintenance and easy replacement of knives and sieves.

8 + 1 Reasons to Choose an WHC High-Speed Mill

We use first-class alloy steel. Key components prone to wear and tear undergo heat treatment and wear-resistant coating for increased durability.

NašeOur shredders are equipped with high-performance motors that ensure exceptional stability and efficiency, optimized crushing performance, and minimal downtimes.

The integrated hydraulic system simplifies sieve changes and allows easy opening and closing of the machine body. It also provides quick access for cleaning and changing blades.

Our electrical control system includes high-end components. The Schneider/ABB electronics core is a part of standard equipment.

WHC high-speed mills offer excellent prices without compromising on quality, making them the ideal solution for demanding plastic recycling applications.

The design includes highly durable plates along the main shaft to protect the machine body from corrosion and abrasion, extending running life even after extended use.

The V-shaped rotor configuration improves material flow control in the shredding zone. This design innovation reduces material dispersion, minimizes power loss, and improves overall shredding efficiency compared to traditional rotor designs.

Both the rotor and stator blades are made from D2 steel, which is known for its excellent wear resistance and extended running life, ensuring better long-term performance.

Models with more than five rows of knife blades have a standard blade adjustment jig. This jig reduces blade change time and increases operating efficiency, ensuring faster turnaround and sustained high performance.

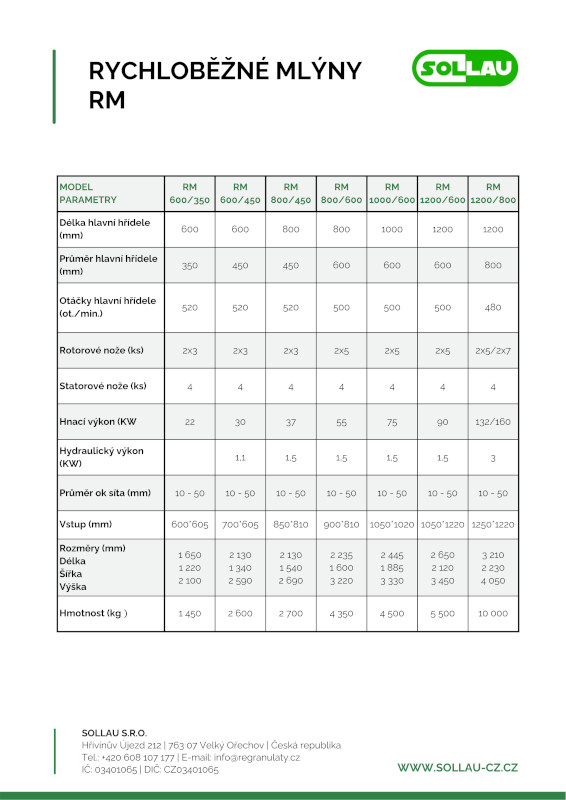

WHC shredders are available in several variants according to the capacity and customer requirements:

| Model ParameterS |

WHC 600/350 | WHC 600/450 | WHC 800/450 | WHC 800/600 | WHC 1000/600 | WHC 1200/600 | WHC 1200/800 |

|---|---|---|---|---|---|---|---|

| Main shaft length (mm) | 600 | 600 | 800 | 800 | 1000 | 1200 | 1200 |

| Main shaft diameter (mm) | 350 | 450 | 450 | 600 | 600 | 600 | 800 |

| Main shaft speed (rpm) | 520 | 520 | 520 | 500 | 500 | 500 | 480 |

| Rotor knives (pcs) | 2x3 | 2x3 | 2x3 | 2x5 | 2x5 | 2x5 | 2x5/2x7 |

| Stator knives (pcs) | 4 | 4 | 4 | 4 | 4 | 4 | 4 |

| Driving power (kW) | 22 | 30 | 37 | 55 | 75 | 90 | 132/160 |

| Hydraulic power (kW) | 1,1 | 1,5 | 1,5 | 1,5 | 1,5 | 3 | |

| Sieve mesh diameter (mm) | 10 - 50 | 10 - 50 | 10 - 50 | 10 - 50 | 10 - 50 | 10 - 50 | 10 - 50 |

| Input (mm) | 600x605 | 700x605 | 850x810 | 900x810 | 1050x1020 | 1050x1220 | 1250x1220 |

| Dimensions (mm) Length Width Height |

1 650 1 220 2 100 |

2 130 1 340 2 590 |

2 130 1 540 2 690 |

2 235 1 600 3 220 |

2 445 1 885 3 330 |

2 650 2 120 3 450 |

3 210 2 230 4 050 |

| Weight (kg) | 1 450 | 2 600 | 2 700 | 4 350 | 4 500 | 5 500 | 10 000 |

- Main shaft length: 600 (mm)

- Driving power: 22 kW

- Inlet opening: 600 x 605 mm

- Capacity: 300 - 600 kg/h

| Model | Main shaft length (mm) | Main shaft diameter (mm) | Main shaft speed (rpm) | Rotor knives (pcs) | Stator knives (pcs) |

|---|---|---|---|---|---|

| WHC 600/350 | 600 | 350 | 520 | 2x3 | 4 |

| Model | Driving power (KW) | Hydraulic power (KW) | Sieve mesh diameter (mm) | Input (mm | Dimensions (L x W x H) (mm) | Weight (kg) |

|---|---|---|---|---|---|---|

| WHC 600/350 | 22 | 10 - 50 | 600x605 | 1650*1220*2100 | 1 450 |

- Main shaft length: 600 (mm)

- Driving power: 30 kW

- Inlet opening: 700 x 605 mm

- Capacity: 300- 600 kg/h

| Model | Main shaft length (mm) | Main shaft diameter (mm) | Main shaft speed (rpm) | Rotor knives (pcs) | Stator knives (pcs) |

|---|---|---|---|---|---|

| WHC 600/450 | 600 | 450 | 520 | 2x3 | 4 |

| Model | Driving power (KW) | Hydraulic power (KW) | Sieve mesh diameter (mm) | Input (mm | Dimensions (L x W x H) (mm) | Weight (kg) |

|---|---|---|---|---|---|---|

| WHC 600/450 | 30 | 1,1 | 10 - 50 | 700x605 | 2130*1340*2590 | 2 600 |

- Main shaft length: 800 (mm)

- Driving power: 37 kW

- Inlet opening: 850 x 810 mm

- Capacity: 500 - 800 kg/h

| Model | Délka hlavní hřídele (mm) | Průměr hlavní hřídele (mm) | Otáčky hlavní hřídele (ot./min.) | Rotorové nože (ks) | Statorové nože (ks) |

|---|---|---|---|---|---|

| WHC 800/450 | 800 | 450 | 520 | 2x3 | 4 |

| Model | Driving power (KW) | Hydraulic power (KW) | Sieve mesh diameter (mm) | Input (mm | Dimensions (L x W x H) (mm) | Weight (kg) |

|---|---|---|---|---|---|---|

| WHC 800/450 | 37 | 1,5 | 10 - 50 | 850x810 | 2130*1540*2690 | 2 700 |

- Main shaft length: 800 (mm)

- Driving power: 55 kW

- Inlet opening: 900 x 810 mm

- Capacity: 500 - 800 kg/h

| Model | Main shaft length (mm) | Main shaft diameter (mm) | Main shaft speed (rpm) | Rotor knives (pcs) | Stator knives (pcs) |

|---|---|---|---|---|---|

| WHC 800/600 | 800 | 600 | 500 | 2x5 | 4 |

| Model | Driving power (KW) | Hydraulic power (KW) | Sieve mesh diameter (mm) | Input (mm | Dimensions (L x W x H) (mm) | Weight (kg) |

|---|---|---|---|---|---|---|

| WHC 800/600 | 55 | 1,5 | 10 - 50 | 900x810 | 2235*1600*3220 | 4 350 |

- Main shaft length: 1,000 (mm)

- Driving power: 75 kW

- Inlet opening: 1,050 x 1,020 mm

- Capacity: 700 - 1,000 kg/h

| Model | Main shaft length (mm) | Main shaft diameter (mm) | Main shaft speed (rpm) | Rotor knives (pcs) | Stator knives (pcs) |

|---|---|---|---|---|---|

| WHC 1000/600 | 1000 | 600 | 500 | 2x5 | 4 |

| Model | Driving power (KW) | Hydraulic power (KW) | Sieve mesh diameter (mm) | Input (mm | Dimensions (L x W x H) (mm) | Weight (kg) |

|---|---|---|---|---|---|---|

| WHC 1000/600 | 75 | 1,5 | 10 - 50 | 1050x1020 | 2445*1885*3330 | 4 500 |

- Main shaft length: 1,200 (mm)

- Driving power: 90 kW

- Inlet opening: 1,050 x 1,220 mm

- Capacity: 1,000 - 1,500 kg/h

| Model | Main shaft length (mm) | Main shaft diameter (mm) | Main shaft speed (rpm) | Rotor knives (pcs) | Stator knives (pcs) |

|---|---|---|---|---|---|

| WHC 1200/600 | 1200 | 600 | 500 | 2x5 | 4 |

| Model | Driving power (KW) | Hydraulic power (KW) | Sieve mesh diameter (mm) | Input (mm | Dimensions (L x W x H) (mm) | Weight (kg) |

|---|---|---|---|---|---|---|

| WHC 1200/600 | 90 | 1,5 | 10 - 50 | 1050x1220 | 2650*2120*3450 | 5 500 |

- Main shaft length: 1,200 (mm)

- Driving power: 132/160 kW

- Inlet opening: 1,250 x 1,220 mm

- Capacity: 1,000 - 1,500 kg/h

| Model | Main shaft length (mm) | Main shaft diameter (mm) | Main shaft speed (rpm) | Rotor knives (pcs) | Stator knives (pcs) |

|---|---|---|---|---|---|

| RM 1200/800 | 1200 | 800 | 480 | 2x5/2x7 | 4 |

| Model | Driving power (KW) | Hydraulic power (KW) | Sieve mesh diameter (mm) | Input (mm | Dimensions (L x W x H) (mm) | Weight (kg) |

|---|---|---|---|---|---|---|

| WHC 1200/800 | 132/160 | 3 | 10 - 50 | 1250x1220 | 3210*2230*4050 | 10 000 |

Dimensional table of WHC high-speed mills

Dimensional table of WHC high-speed mills

Download PDF

(velikost 72 kB)